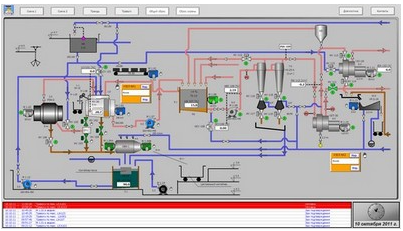

The process control system of the waste paper preparation section made it possible to start the equipment in manual / semi-automatic and fully automatic modes.

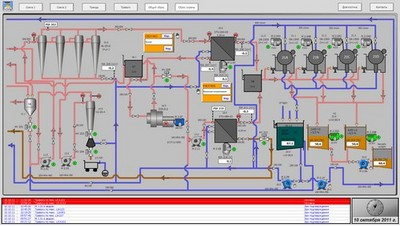

The system is divided into 5 nodes, each of which controls a separate part of the site.

General view – 1

The main functions are laid down:

– the correct order of turning on and off the nodes of the site;

– equipment operation in the required mode;

– observance of the washing condition to exclude unwanted compaction with paper pulp;

– level control in pools

– equipment operability control;

– various interlocks during the operation of the equipment;

– issuance of emergency messages to prevent failure of the technological line and minimize financial losses;

– data archiving for further analysis;

– obtaining the purification of the mass of the required quality;

– maximum exclusion of the human factor.

The system is made using equipment of the following brands:

– TVD control cabinet;

– Siemens PLC;

– Wago terminals;

– Relay Finder;

– Schneider power supplies;

– Visualization WinCC;

– Network equipment Asus;

– Marking Weidmuller.

General view – 2

The equipment available at the enterprise was used as floor equipment.

Order code: TS-PM010.00-00