Description of the technological object

The technological object of control is a part of the paper machine from the headbox to the roll-up. The PM control system includes the following subsystems:

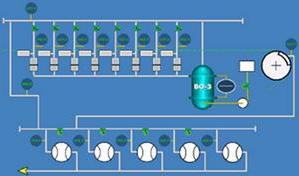

– vacuum system control;

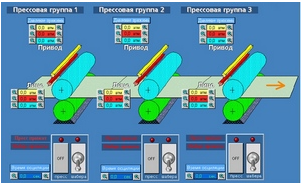

– press control;

– control of the tension of felts;

– control of the steam condensate system;

– control of scrapers of the drying section;

– coasting control;

– ventilation control;

– pump control;

– control of the scanning device.

purpose of the process control system

The main task is to control the process control system as a unified system, taking into account the necessary algorithms.

technical solution

A Siemens / Mitsubishi programmable logic controller is used as the basic element of the process control system.

Visualization is performed on SCADA system WinCC / Citect. Cable products from LappKabel.

The construction of the system is carried out in such a way that the subsystems operate in the following modes:

– local – control is carried out manually, local control panels are used;

– remote-manual – control is carried out manually, using the “SCADA” system console;

– remote-automatic – control is carried out by the controller according to a given algorithm (in those subsystems where it is necessary).

APCS PM

Unit standardization and structural design based on Siemens / Mitsubishi industrial controllers will allow the system to be serviced by trained personnel.

The system has an open architecture and can be easily upgraded to carry out the next stages of work on the modernization of the process control system. Further build-up of the system will make it possible to create a unified control system for the entire paper machine with a unified control structure.

APCS PM

Results and effect of implementation

The PM control system will allow the functioning of all PM control subsystems as a whole and, as a result, significantly improve the quality of the products.

Establishing feedback from the quality control system on the parameters of weight, moisture, ash content in automatic mode will significantly improve the competitiveness of the products.

The payback period for the implementation of the system, depending on the configuration, will be from 3 to 12 months.

Order code: TS-PM007.01-00