The VPP-V meter is designed for non-contact moisture measurement of paper, cardboard, bulk materials, shavings, wood chips, chipboard, fiberboard, compound feed, cellulose, etc. The meter can operate autonomously and be integrated into other enterprise APCS systems.

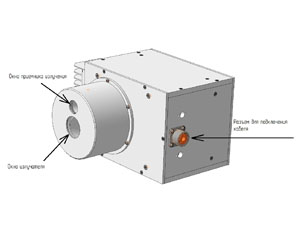

Measuring sensor

moisture. Unilateral type.

The principle of moisture measurement is based on determining the intensity of infrared (IR) radiation reflected from the controlled material. For the humidity range from 2 to 20%, the measurement is carried out at a wavelength of 1.93 microns, providing the highest sensitivity to the measured parameter and achieving the required measurement accuracy. To reduce the influence of non-informative parameters, the controlled material is also irradiated with infrared radiation with a wavelength of 1.75 µm, which is practically little absorbed by water (reference wavelength).

The sensor, working on the principle of optical reflection, is operated with a working gap of 50 – 150 mm and an ambient temperature of +10 to +50 degrees. C. It is possible to use it as a laboratory instrument for measuring humidity by express method.

The burned sensor is calibrated for a specific type of material. Prerequisite: the presence of a continuous flow of the measured material (belt conveyor or hopper with a moving continuous mass).

The sensor processes the received reflected signal from the sample and carries out digital transmission to a computer with an installed display program. As a mainframe the industrial computer is added.

System screen

High precision and reproducibility. To increase the accuracy, an automatic sensor based on an internal sample and thermostating of the photodetector are used.

Lack of liquid cooling systems. The sensor is cooled by the ambient air.

An original algorithm for correcting the dependence of the signal on the distance. The algorithm developed by our company almost completely eliminates the effect of the distance to the controlled object, which is especially important when measuring the moisture content of materials such as shavings, wood chips, etc.

There is a modification of the sensor for measuring the moisture content of the carpet material in the flow in the range from 30% to 80%.

The ability of the system to work as part of an automated process control system to regulate the drying process of chips, resin dosage.

Implementation details:

Plitspichprom JSC, Balabanovo, Kaluga region, Russia – 1 set.

Moscow exp. chipboard plant, pos. Podrezkovo, Moscow region, Russia – 8 sets

OJSC “Avers”, Kiev, Ukraine – 1 set.

OJSC PTO Shatura, Shatura, Moscow region, Russia – 2 sets.

DOK Krasny Oktyabr OJSC, Tyumen, Russia – 2 sets.

JSC “Elektrogorsk Mebel”, Moscow region, Russia – 2 sets.

JV “Interplit”, Nadvirna, Ivano-Frankivsk region, Ukraine – 2 sets.

Proletary OJSC, Surazh, Bryansk region, Russia – 5 sets.

JSC “Rubezhanskiy CPC”, Lugansk region, Ukraine – 1 set.

Perm Plywood Mill, pos. Ural, Perm region, Russia – 1 set

technical certificate

Order code: TT-AA005.04-00 – moisture meter in the process stream (IPB-O) (4 measurement channels)

Order code: TT-AA005.01-00 – moisture meter in the process stream (IPB-O) (1 measurement channel)

Order code: TT-AA005.10-00 – additional measuring channel for IPB-O