The automated process control system (APCS) for sugar drying is designed to improve the technical and economic performance of the sugar drying department, equipped with a drum-type drying unit, by general stabilization of technological parameters.

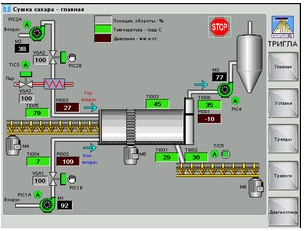

General view of the circuit

The functioning of the system is based on automated control of technological processes of drying, cooling and transportation of granulated sugar in the sugar drying department, namely:

– cold and hot air pressure;

– steam (hot air) temperature;

– the degree of vacuum of the exhaust fan;

– sugar temperature.

Based on the analysis of the parameters, the control system determines the current operating mode of the sugar drying department and identifies the need to change the ratio of hot and cold air.

APCS equipment based on Siemens S7-315 PLC with visualization on the Schneider Magelis panel. Automatic control of the temperature of hot and cold air provides high technological indicators of sugar drying.

Due to the automated control and monitoring of parameters, the process control system allowed to reduce energy costs, increase the productivity of the sugar drying department, ensure reliable protection of technological equipment and high quality of sugar drying.

Order code: FD-SU001.00-00