APCS PPS PM is designed to operate in a fully automatic mode of the drying section of the paper machine.

The algorithm of work of the automated process control system for drying paper on a paper machine is designed on a turnkey basis, depending on:

– technological process;

– used equipment of objects of measurement;

– used equipment of control objects;

– drying technologies;

– used controllers;

etc.

It is possible to use controllers from different manufacturers. In an industrial controller, all information from the sensors is digitally processed, used as input information for the built-in PID controllers, with subsequent action on the controls.

APCS PPP is tied to the quality control system of our company, it allows you to start the humidity control mode in manual mode, in automatic mode, and in the “cascade” mode.

It is possible to install an additional moisture sensor in front of the size press (if there is one) and introduce another control loop (regulation of paper moisture in front of the size press and moisture regulation before reel).

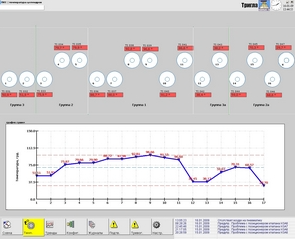

Information about all processes in the plant is displayed on the operator panel for full control over the operation of the drying process.

Cylinder temperature

Since the solution is carried out on a turnkey basis, it is possible to create an automated process control system based on existing controls, as well as design, calculate and purchase the necessary elements from leading manufacturers.

The use of the APCS will provide the Customer with the following advantages:

– The system is tied to a break sensor, which allows you not to overheat the drying and save steam

– The system provides an analysis of the work of teaching staff according to the schedules

– The system is linked with a quality control system, which allows to wring the paper of the required moisture content and reduces product rejects during production and rewinding;

– Display of all parameters of the PPP in one place (on one screen) for precise adjustment of the PPP for the required drying process of the produced paper;

– Maintaining recipes for PPP settings for various types of paper;

– The use of digital PID controllers for fast and intelligent reconfiguration of the controller when changing an actuator or sensor.

It is possible to add cylinder temperature sensors to the system to obtain an online temperature graph. The system can be developed both as a stand-alone version and on the basis of a PLC quality control system.