The introduction of modern information technologies, as well as the latest developments in the field of industrial automation of grain storage and processing enterprises, has a significant impact on improving management efficiency, increasing the competitiveness of enterprises in general.

The process of storage and processing of grain is complex, multi-stage, energy-intensive, requiring the implementation of perfect, reliable automation systems for storage and processing of grain to achieve high efficiency in this industry. The technology of storage and processing of grain has been improved for centuries, from the moment man first learned to grind grain using rotating stones tightly adjacent to each other. Today, the same grinding and impact mechanisms are used for grain processing, only on the basis of fully automated, technically advanced technological complexes for processing and storing grain. The number of monitored as well as control parameters of modern automated grain storage and processing enterprises (elevators, granaries, flour mills, feed mills) is constantly increasing, having long exceeded the border when the operator can independently (without the use of complex automated complexes for grain storage and processing enterprises) manage technological process. In this regard, the issues of introducing complex automation of grain storages, elevators, silos and other facilities for processing and storage of grain is very relevant.

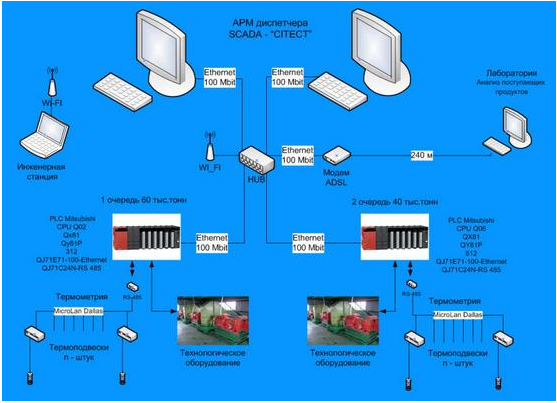

System block diagram

Drying, storage, movement of grain are the main components of the grain processing process. Automation of technological processes of drying, storage of grain, as a rule, is carried out at a fairly high level. The main obstacle to the introduction of modern automated process control systems for grain transfer is their relatively high cost.

Control cabinets

The technical basis for increasing the efficiency of grain storage and processing technology, organizing automatic control, management, and quantitative accounting of raw materials and products is an automated control system for technological processes of grain storage and processing. The automated process control system for storage and processing of grain performs operational, strict control of raw materials and products, monitors the compliance of the enterprise with technological regulations, controls the actions of technological personnel, increases the personal responsibility of operators for decisions that have caused losses.

Control room

The main directions of automation of technological processes of storage and processing of grain: Introduction of new generation systems – computerized automated complexes of grain processing enterprises and storages instead of relay systems for automated control of grain storage and processing existing at many enterprises of the industry. Modernization of the automated process control system of grain storage and grain processing complexes will allow to efficiently control the technological process, control, record the actions of operators, keep a strict record of raw materials and products.

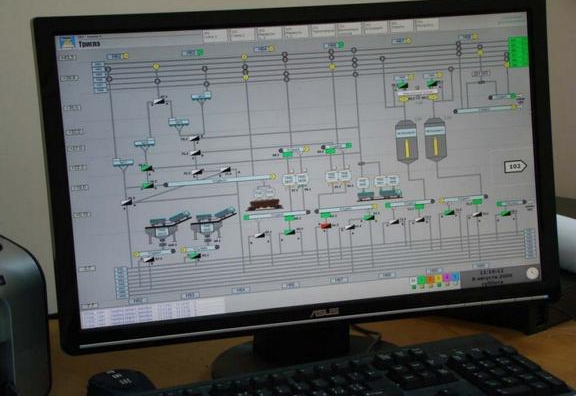

Mnemonic diagram

The introduction of modern automation systems for grain storage and processing enterprises makes it possible to qualitatively prepare grain for grinding, including the formation of a grinding batch, optimal automatic moistening of grain, depending on the initial moisture content, as well as a number of other characteristics.

Replacement of relay control systems for elevators, silos with modern element base of grain storage automation systems will make it possible to actually track the movements of each specific batch of grain, maintain continuous accounting, promptly analyze grain parameters, tightly control the acceptance process, and reduce the likelihood of shortages.

Implementation of modern commercial accounting systems at a grain storage and processing enterprise using strain-gauge weighing systems connected by a single automated grain (grain products) accounting system, available for reading readings from the upper level of the automated process control system of a grain processing enterprise.

Automated accounting of products of grain processing enterprises and granaries significantly reduces the influence of the human factor on the weighing result and increases the accuracy of measurements. Replacement of outdated elevator and silo thermometry systems with modern metrologically certified and certified systems.

The task of automating the complex for the storage and processing of grain is very urgent today. Modern means of automated process control systems of grain processing enterprises can significantly reduce losses during storage and processing of grain, save energy resources of grain processing enterprises, elevators, minimize the influence of the human factor, the risks of emergencies in the operation of automated technological complexes for storage and processing of grain. The latest developments in the field of automated process control systems of the grain processing industry make it possible to automatically predict the process of self-heating of grain, reliably, efficiently and automatically control the flows of wet and dry grain, the drying process, as well as a system for forming technological routes within the grain processing enterprise.

Technical documentation

Order code: AG-AA001.00-00