Centralized CIP cleaning and disinfection of equipment and pipelines is one of the key elements of ensuring and maintaining proper sanitary and hygienic conditions in modern food production. The correct construction and operation of such systems allows not only to ensure the release of safe and high-quality products, to increase its shelf life, but also to significantly reduce the current costs of the enterprise for monitoring procedures for technological processes and products, and to increase the efficiency of modern quality management systems.

The CIP control system is designed to automatically perform the following main functions:

– rinsing;

– washing with alkali;

– acid washing

– thermal disinfection;

– chemical disinfection;

– preparation of alkali solution;

– preparation of acid solution.

Main advantages:

– Possibility of multiple use of cleaning solutions;

– Ability to wash several objects at the same time;

– Automatic maintenance of temperature and concentration of washing solutions;

– Heating water in a small circuit saves time, water and energy;

– Individual washing programs for various objects;

– It is possible to promptly change the algorithms and logic of work based on the characteristics of the control object at a particular enterprise;

– Function of feedback with objects of washing;

– Registration and storage of performed operations;

– reduction of the total washing time due to the optimization of the heating programs;

– Diagnostics of emergency situations, sound and light notification, identification of failed station nodes.

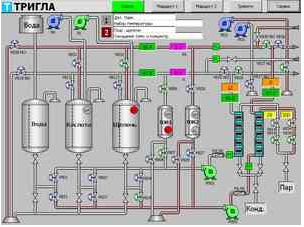

Общий вид схемы

Much attention is paid to service maintenance, which allows you to configure and turn on equipment from different manufacturers with different initial parameters.

Operator interface and control system are made on Siemens equipment.

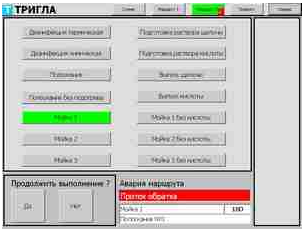

Washing programs

The construction allows you to install the process control system both on a single-circuit and on a multi-circuit on a new or on an existing one, but does not satisfy, for some reason, a station at the enterprise.